Parts numbers packaging data transportation data and stock data eg. By Sunderesh Heragu and.

The Logistics Cycle Shows The Different Functions Of The Logistics Download Scientific Diagram

The application of linear programming by the General Electric Company to efficiently allocate routes to trucking companies.

. Logistics System Design Supply Chain Management. Weigh-In-Motion System Market- Growth Prospects Competitor Analysis Regional Insights Market Trend Analysis Forecast to 2026 - Global weigh-in-motion system market is set to witness a substantial CAGR of 891 in the forecast period of 2019- 2026. Low moderate or high used to describe attributes of transportation modes.

Design of large-scale logistics systems for uncertain environments. In fact it is quite evident to find out how by using simulation. The system can take an order to deliver it to a given destination.

Logistics Systems Design Chapter 1. Transportation Models Presentation Slides. The core idea is to spatially decouple production indus-trial robots and logistics flow of goods.

The report contains data of the base year 2018 and historic year 2017. Save Time Money - Start Now. Customer orders production plan as well as superordinate parameters of.

A tried-and-tested standardised process model for recording and mapping such values is the LOGSOL logistics matrix which is also used as a web-based application. Product Design Logistics. Obviously these are strategic decisions because they have a long-standing e ect on the rm.

On the x axis place the main elements for developing your supply chains. Matrix Ai j present if. 10 LOgiSTiCS SySTEM dESign 3.

First week only 499. On the basis of master data eg. Rail is associated with Multiple Choice 40 low volume hic cost and low speed moderate volume tigh speed and high cost moderate volume moderate speed and high cost.

Matrix production promises not only maximum capacity utilization but also the decoupling of humans as logistics service providers from the machine cycle production. Ad No Matter Your Mission Get The Right Logistics Management Systems To Accomplish It. To begin constructing the supply chain strategy for your enterprise build a matrix.

The design matrix is used in certain. He success of a system design is deined by how efective and eicient the system is in practice. Lets assume we want to design a Logistics System with following basic functionality.

The design of products for manufacturing packaging shipping warehousing merchandising and repackaging for returns. No matter how well it is designed the system will fail without a well-planned. Rail is associated with moderate volume high speed and high cost low volume high cost and low speed high volume moderate speed and low cost See exhibit 151.

Client-centered supply chains provide a dependable supply of quality affordable contraceptives of clients choice that are available when and where clients want them. The Logistics Network consists of. Reducing costs and environmental impactSimplifying planning and improving operational efficiencyMarketing benefits such as products that look good on shelves.

Each row represents an individual object with the successive columns corresponding to the variables and their specific values for that object. The logistics system helps in defining the series of the task form the supplier to the end-users this. As discussed in the textbook the sourcingpurchasing design matrix includes three variables contract duration transaction cost and specificity assumes levels as short medium and long for contact duration and for the rest low medium and high.

Find an answer to your question In the logistics-systems design matrix volume cost and speed of delivery are three variables assume three levels. On the y axis identify your selection of say four attributes from the above list that best describes the Availability objectives of your organisation. PlantsVendors Ports Warehouse RetailersDistribution Centers.

The order will be a list of items and there is a cost of each order to process. The system can use for making the sequences of the activity. In statistics and in particular in regression analysis a design matrix also known as model matrix or regressor matrix and often denoted by X is a matrix of values of explanatory variables of a set of objects.

In the logistics systems design matrix volume cost and speed of delivery are three variables assume three levels. Solution for Explain Logistics-System Design Matrix. Well-designed family planning logistics systems let clients needs direct the supply chain.

Start your trial now. Review the Best Logistics Management Systems for 2022. The Logistics NetworkI The objective of this chapter is to present some issues involved in the design and con guration of the logistics network.

Air is associated with. Matrix an algorithm to assign resources and finally. In the logistics-systems design matrix volume cost and speed of delivery are three variables assume three levels.

Logistics systems in the process industry an approach for simulation and a detailed discussion on a. Low moderate or high used to describe attributes of transportation modes. Programs can ensure clients receive the supplies.

Implementing a logistics system is a dynamic process that requires ongoing training monitoring and evaluation. Vendor managed inventory belongs to. The proposed platform represents the first step towards developing an expert system capable of supporting the integration of planning design management control and optimization activities in a flexible production distribution system.

User has to register himself herself to use this system. Low moderate or high used to describe attributes of transportation modes. Logistics design and modelling is a typical environment where simulation can be considered a useful device.

The proposed tool is composed of strongly interrelated different decision modules. Long contract duration low transaction cost high specificity. There exist a vast amount of literature software packages decision support tools and design algorithms that focus on isolated components of the supply chain or isolated planning in the supply chain.

In the logistics-systems design matrix volume cost and speed of delivery are three variables assume three levels. Production parts tools and reconnect them using mobile robotics. Build a matrix.

Download Free PDF Download Free PDF View PDF. Weve got the study and writing resources you need for your assignments.

Er Diagram Of The Most Important Tables In A Logistics Management System Download Scientific Diagram

Ecommerce Tools Matrix It Mcommerce Online Store Builder Infographic

Logistics Decision An Overview Sciencedirect Topics

Product Weight And Size Usage Of Recycled Materials Energy Consumption Supply Management Supply Chain Management Supply Chain

The Logistics Cycle Shows The Different Functions Of The Logistics Download Scientific Diagram

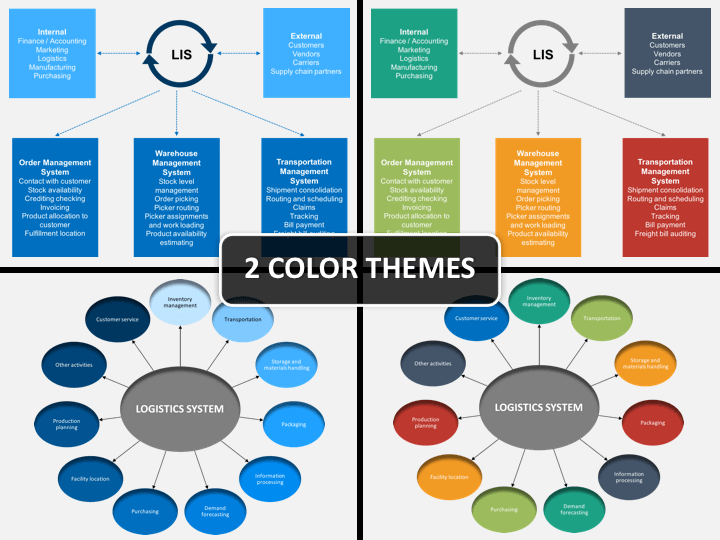

Logistics Information System Powerpoint Template Sketchbubble

Supply Chain Management Supply Chain Management Chain Management Data Science

0 comments

Post a Comment